Atlas Element Achromatic 2 RCA to 2 RCA Audio Cable Pair - 2m

Atlas have made greater improvements on their new Element Achromatic Audio cable to create a higher performance starting point that delivers zero "colourisation" based upon their many years of knowledge and value for money characteristics. By improving the core elements of the Element Achromatic audio cable, the overall performance is greatly improved for an entry level cable. This means Atlas Element Achromatic audio cable can offer fantastic performance for most hi-fi systems due to it's minimal "colourisation" and greater bandwidth capabilities over and above the original Atlas Element Integra.

Features:

- Achromatic RCA Plug

- OCC Copper

- Polyethylene (PEF) Dielectric

- Co-ax Construction

Recommended Products

Customer Also Viewed

Samma3a Review

Technical Specification

- Construction: Coax

- Conductor Material: OCC Copper

- Screen Type/Material: Braid OFC

- Screen Coverage %: 90%

- Dielectric: PEF

- Connector: Achromatic RCA Plug

- Colour: Pearl White

- Outside Diameter : 7.0mm

- Capacitance : 63.03 pF/m

- Inductance : 0.3735 µH/m

- Resistance : 0.1612Ω/m

- Impedance : 77.05 Ohms/m

- Warranty: 1 year

What Is In The Box

- Atlas Element Achromatic 2 RCA to 2 RCA Audio Cable Pair

Videos

Manufacture Description

Achromatic Plugs

Atlas’s expert electro-mechanical knowledge has led to the innovation of the next generation of RCA plugs. Known as the ‘Atlas Achromatic RCA plug’, Atlas has focused on improving both performance and appearance to create a higher performance starting point for their RCA cables as well as eliminating variability in performance. This has been achieved by refocusing on materials and the assembly processes.

Atlas has made 4 key changes with the Achromatic RCA plug. Firstly, the barrel of the Achromatic plug features a high stability ABS material. This is strong, stable and of superlative surface quality.

There is also an improvement to the Achromatic plug’s contact geometry, aiding the contact properties of the plug and the self-cleaning wiping action to ensure contacts are in optimal condition and to maximise signal transmission.

The third change Atlas made was around the rifling of the RCA pin. This improvement self-aligns the conductors during the cold weld processing, ensuring a superior stable connection.

Finally, there is a reduction in the overall mass of the RCA plug by 8% which has shown to improve signal transmission.

The above changes mean a solder-free, low mass, self-cleaning, recyclable RCA plug with a non-conductive body.

OCC Copper

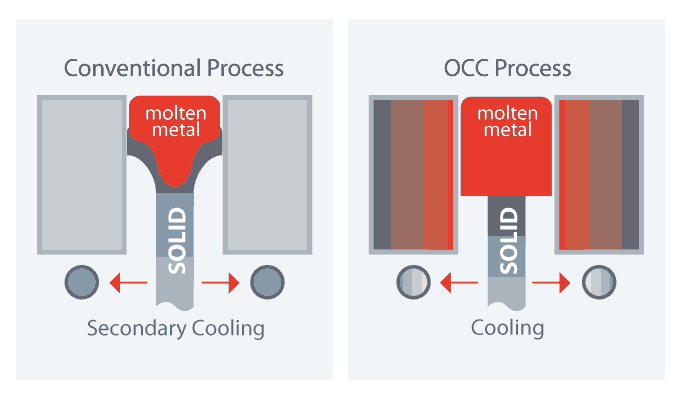

The Ohno continuous casting method re-heats the extrusion as the molten copper is forced out of the mould and very slowly and gradually draws the grain or crystal down the conductor''s length, creating a ‘single crystal structure.’ Actually, because no copper is 100% pure, there will always be a few boundaries produced by impurities. The frequency of boundaries created are quite insignificant. A typical crystal in a copper conductor drawn to 0.3 mm diam. using the OCC process is 125.00 metres long! The benefits are obvious, with almost no crystal boundaries, the audio signal is no longer impeded down the copper wire and more information and detail is delivered faithfully to the receiving equipment.

BHD

BHD JOD

JOD KWD

KWD LBP

LBP OMR

OMR QAR

QAR SAR

SAR USD

USD